0 to

Water Cooled Modular and Process Glycol Chiller Danfoss/Copeland Scroll Type Compressor Water Cooled Water Modular Chill

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | WW80-160 |

| Application Fields | Industry |

| Application Machine | Industry |

| Certification | CE |

| Condition | New |

| Energy Recovery | Optional |

| PLC Control | Optional |

| Electric Parts | Schneider Brand |

| Refrigerant Valves | Emerson/Danfoss |

| Closed Box | Optional |

| Heat Exchanger | Shell and Tube |

| BMS Control | Optional |

| Water Inlet/Outlet Temp | 12/7(Max-20degree) |

| Refrigerant | R22/R407c/R410A/R134A/R404A |

| Compressor | Danfoss/Copeland/Panasonic |

| Transport Package | Lastic Film Wrapped |

| Specification | 80kw-160kw |

| Trademark | Amrta or OEM |

| Origin | China |

| HS Code | 8418612090 |

| Production Capacity | 5000PCS/Year |

Product Description

Water Cooled Modular and Process Glycol Chiller

Danfoss/Copeland Scroll Type Compressor Water Cooled Water Modular Chiller

Cooling Capacity 80 kW ~ 160 kW

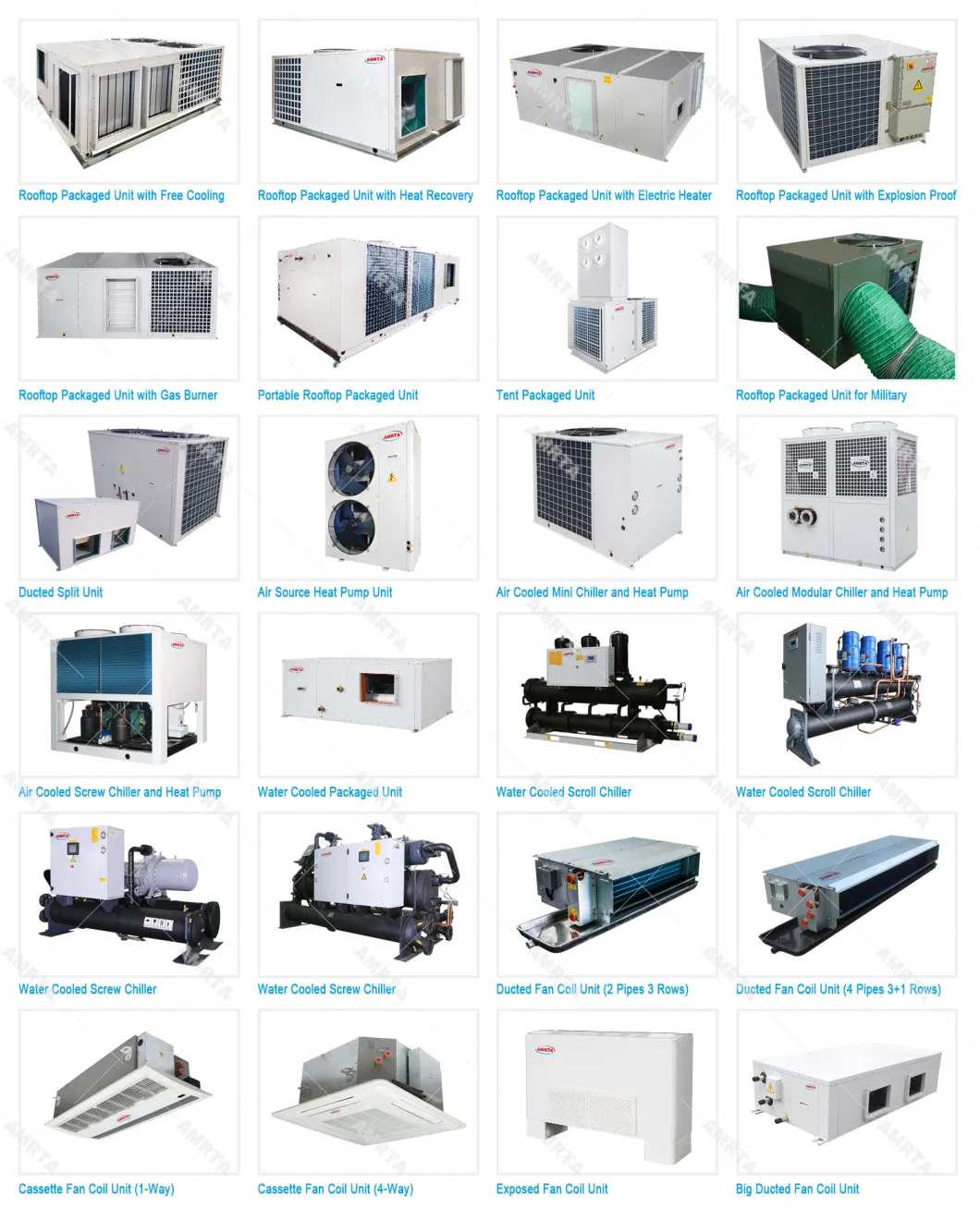

Our Products Range

Product DescriptionThe master module can work independently or together with up to 7 slave modules, flexible design, stable performance, easy maintenance.Reusable: using solar energy stored in earth as cooling & heating source.Panels and frame are made from galvanized steel protected with polyester powder painting to ensure total resistance to atmospheric agents.3-phase scroll type compressor, with built-in thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers.Shall and tube type evaporator, factory insulated with flexible close cell material.Shall and tube dry expansion type condenser, factory insulated with flexible close cell material.The refrigerant circuit is complete with filter drier, direct expansion valve, high and low pressure switch.Acting as multi-function unit such as cooling, heating, with heat recovery function producing hot water for domestic use.LCD display as standardAutomatic operation dramatically reducing maintenance cost thanks to reliable microprocessor system.Wide application as hotel, apartment, villa, factory, shopping center, office building, school, etc. ELECTRIC PANELconsists of:Compressor breaker,Compressor contactorPhase sequence relayControl circuit breakerMicroprocessor with function displayOPTIONALDesuperheater as optionalElectronic controller with BMS system.

Technical Data

| Model | WW80 | WW120 | WW160 | |

| Refrigerant | R22/R410a | R22/R410a | R22/R410a | |

| Water cooled conditions | Cooling capacity(kW) | 80 | 120 | 160 |

| Cooling power input(kW) | 15.5 | 23.5 | 31.0 | |

| Compressor | Type | Danfoss/Copeland scroll compressor | ||

| Power input | 380V/3N-50Hz | |||

| Qty | 2 | 3 | 4 | |

| User side heat exchanger | Type | Shell and tube heat exchanger | ||

| Water resistance(kpa) | 40-60 | |||

| Fouling factor(m²·ºC/kw) | 0.086 | |||

| Pipe size (mm) | DN65 | DN80 | ||

| Connetion type | Flange | |||

| Water flow rate(m³/h) | 13.8 | 20.5 | 27.5 | |

| Source side heat exchanger | Type | Shell and tube heat exchanger | ||

| Water resistance(kpa) | 40-60 | |||

| Fouling factor(m²·ºC/kw) | 0.086 | |||

| Pipe size (mm) | DN65 | DN80 | ||

| Connection type | Flange | |||

| Water flow rate(m³/h) | 16.5 | 24.5 | 32.8 | |

| Dimension | Length(mm) | 2110 | 2110 | 2530 |

| Width(mm) | 620 | 620 | 650 | |

| Height(mm) | 1365 | 1365 | 1410 | |

| Noise level≤dB(A) | 67 | 67 | 67 | |

| Unit weight(kg) | 560 | 800 | 1050 | |

Performance values refer to the following conditions:* Source side water inlet/outlet temperature 18ºC/29ºC, user side water inlet/outlet temperature 12ºC/7ºC, for Underground water ** Sound pressure measured at a distance of 1 m and a height of 1.5 m above the ground in a dear field.

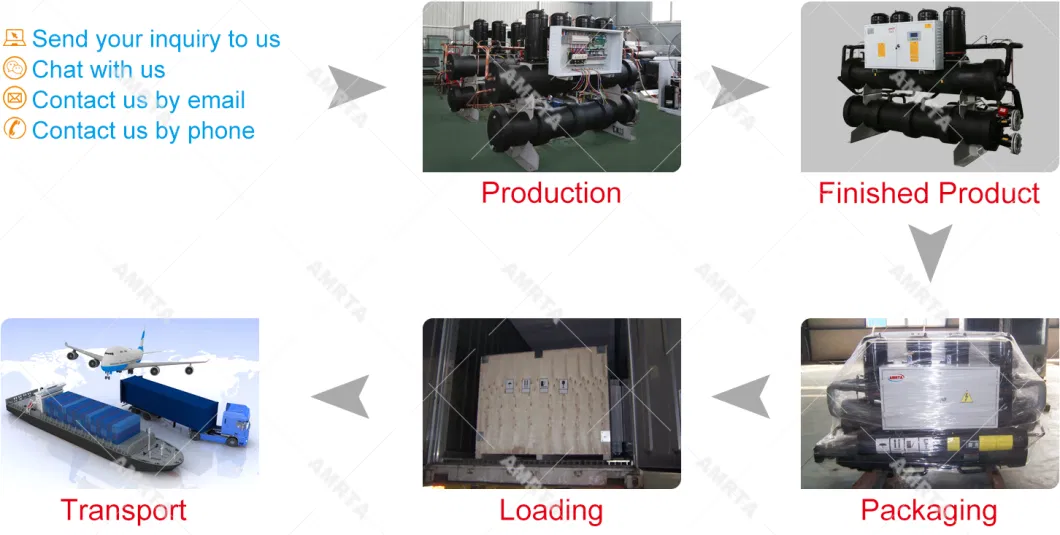

Production Process

Explosion PicturesUnit PicturesOur Factory and CertificatesSome Overseas Simple ProjectsContact Us